KM24

Uses: Knife Making

Long lasting solid state relay

Our KM base line features a solid-state relay, which outlasts standard mechanical relays and provides superior temperature control during holds. With no moving parts, solid-state relays are highly durable and operate silently—you'll only hear the reassuring hum of the heating elements. To ensure optimal performance, the relay is mounted on an aluminum heat sink to stay cool. For added safety, a secondary safety relay is included for your peace of mind.

When you own a KM24 furnace, our most popular size, you can live the knife making adventure to the fullest. You will actually witness the birth of your knives in the bright red heat of the furnace. And all Paragon furnaces are now rated to 2350F, so you can fire as hot as you need to.

With a KM-series furnace, the knifemaker can try exotic heat treating methods at his leisure. Does quenching in dry ice really improve blade performance? What happens when 52100 steel is triple-quenched with a one-day wait between each quench? After this treatment, will a 52100 blade bend to 90° without chipping?

With a Paragon furnace in your shop, all questions about heat treating formulas are settled. It is no longer only theory. You find out for yourself what works. Testing and heat treating is at the heart of the knife making adventure. Here is where your confidence as a knife maker takes root.

Experiment with differential hardening, an ancient bladesmith technique. Try out the newest tool steels. Are they really as good as the tried and true D2 and A2? Do they hold an edge yet remain easy to sharpen?

Choose a side swing door or a drop door (We will verify this with you by phone after your purchase).

You can order a Paragon knifemaking furnace with either a drop door or a side-swing door. (The photo above shows the traditional drop door. Scroll down to Options to see the side swing door.) The price of the furnace is the same with either door style.

The drop door opens downward with one-handed operation. A counter-weight handle holds the door securely closed. The door, whether drop or side-swing, is mounted on a heavy-duty 1/2” thick hinge shaft for smooth opening. Because of the rigid case and heavy hinge, the door is sturdy enough for years of faithful service.

Door safety switch

The door micro safety switch shuts off the power to the elements when the door is opened, yet the controller continues to give a temperature readout. The safety switch is standard on Paragon KM furnaces.

Choose from the optional paint colors

As shown in the photos, the standard knifemaking furnaces are painted a deep black, which would look perfect in your shop. You can choose a different paint color at no extra charge.

Solid furnace construction

The furnace is insulated with 3” thick refractory firebrick, which is 1/2” thicker than the standard. The elements are mounted in dropped, recessed grooves machined into the firebrick. This groove protects the element for long life and low maintenance. Elements are simple to replace because they can be lifted directly from the groove. You can replace elements following instructions in the printed manual. The firing chamber is protected by a rigid steel case. A built-in solid stand lifts the firing chamber safely off your worktable. The thermocouple wire is kept inside the control box for protection from the harsh environment of the typical bladesmith shop.

Printed instruction manuals

Your furnace includes a wiring diagram, a controller instruction manual, and a heat treating manual with heat treating instructions for D2, 440C, ATS 34 and 154 CM. The manuals are written in plain English for the beginner.

Made in America

All Paragon furnaces are made in Mesquite, Texas USA. We are proud to support the American worker.

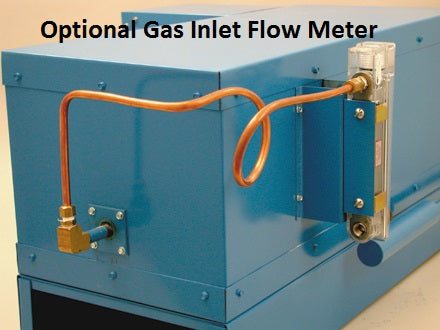

Optional Gas Injection Flow Meter

During heat treating, scale forms on the surface of the steel. One way to eliminate most scaling is to wrap the steel in stainless steel foil. Another way is to install the gas injection flow meter on your furnace. It is available as either an add-on kit, or you can order the furnace with the meter installed.

The meter regulates the flow of an inert gas, such as argon, inside the furnace. The gas displaces the oxygen to prevent some of the scaling. For more details, click on the link in the Options section below.

The knifemaking Kit

In addition to the furnace, you will need a Knifemaking Kit, which separates the blades and holds them parallel inside the furnace. Please click the link below in the Options section.

Thermocouple with “special limit” wireThe thermocouple senses temperature inside the kiln. It is the small rod that extends into the firing chamber. The ¼” wide Type-K, 14-gauge, exposed-tip thermocouple is made with special-limit wire for superior accuracy. The exposed tip gives the controller a fast response time for even temperatures during holds. The thermocouple is made in America to our exacting standards. |

|

Designed for productionParagon’s warranty is not affected by frequency of use. Fire your new kiln every day if you want, even in commercial settings. That will have no effect on the warranty period. |

Specifications

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||