Product Information

- Description

- Additional Options

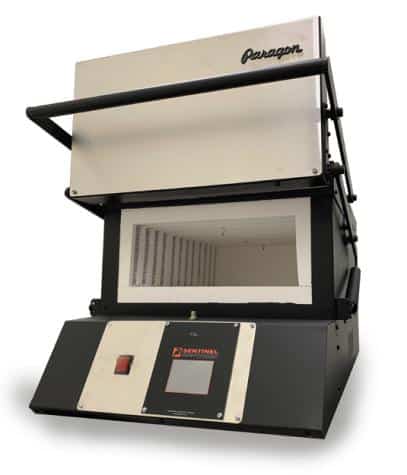

PARAGON KM24 Pro Double Barrel: Built for Bladesmiths Who Think Big

The PARAGON KM24 Pro Double Barrel is made for makers who push the limits—of blade size, batch volume, and thermal control. With its expansive 13.25" wide by 5.25" tall chamber and 24" depth, this kiln offers the interior space professionals need, backed by the advanced 3-zone precision of the KM Pro Series.

Why Have a Heat Treating Furnace in Your Shop?

When you control your heat treatment, you control your results. With the KM24 Pro Double Barrel, you’re not just running blades through a cycle—you’re dialing in soak zones, experimenting with steels, and ensuring every inch of every blade is hardened exactly as intended. Whether you’re heat treating ten blades at once or just one very long one, this kiln makes sure they all come out right.

Why Choose the PARAGON KM24 Pro Double Barrel?

The KM24 Pro Double Barrel gives you industrial-grade features in a format that still fits comfortably in most serious knife shops. With 3-zone control, ceramic fiber insulation, and a chamber built for big work, it offers unmatched flexibility and performance.

-

Interior chamber: 13.25" W x 5.25" H x 24" D (1.00 cubic feet)

-

3-Zone Temperature Control: Three exposed-tip thermocouples (front, center, and rear) monitored independently by the SENTINEL controller to ensure perfect uniformity.

-

Special Limit Thermocouples: Fast-response, 14-gauge exposed tips for precise temperature readings across the entire load.

-

Solid-State Relays: Three SSRs mounted on aluminum heat sinks—quiet, long-lasting, and exceptionally accurate. Includes safety backup relay.

-

2.5” Ceramic Fiber Insulation: Heats faster, cools quicker, and holds tight soak temps with less energy use.

-

Surface-Mounted “Wavy” Elements: Broad, even heating and long element life from wall-mounted layout.

-

Guillotine Door: The spring-assisted vertical-opening door lifts up and away from the user, keeping the hot face safely out of the way and eliminating the need for clearance around the kiln.

-

Heavy-duty steel cabinet with integrated stand: Built for demanding shops and extended duty cycles.

Who is This Furnace For?

The KM24 Pro Double Barrel is ideal for:

-

Bladesmiths making long, wide-profile blades or tools

-

Makers running large batch loads in jigs or fixtures

-

Professionals requiring even temperature across big projects

-

Schools and labs needing consistent, multi-zone thermal control for research or training

Optional Upgrades

-

Gas Injection Flow Meter: Reduce scaling by displacing oxygen in the chamber with argon or other inert gas.

-

Add a solenoid valve: Automatically controls gas flow—active only during programmed segments for added safety.

-

Knifemaking Heat Treating Kit: Includes firebrick supports, blade holders, heat-resistant gloves, and a 31" fork for safe, efficient blade handling.

Built with Pride in Mesquite, Texas

Every PARAGON KM24 Pro Double Barrel is handcrafted in Mesquite, Texas, and reflects decades of experience in furnace design and knifemaking support. When your projects demand more room and more control, this kiln delivers—without compromise.

No specifications available.

Get a Gas Injection Flow Meter (GIFM) and Solenoid Kit

Achieving a clean, scale-free blade finish during heat treatment isn’t just about aesthetics—it’s about quality, consistency, and minimizing post-processing time. The Gas Injection Flow Meter (GIFM) is a trusted tool among professional bladesmiths and heat treaters for precisely that reason.

Minimize Scale, Maximize Results

During high-temperature heat treating, oxygen in the kiln chamber reacts with the steel surface, producing unwanted oxidation scale. Traditionally, this has been mitigated using stainless steel foil wrap—a solution that works, but comes with added cost, time, and waste.

With the GIFM installed, you can introduce an inert gas like argon or nitrogen directly into the firing chamber. This displaces oxygen and significantly reduces oxidation, helping you:

- Eliminate or reduce the need for stainless foil

- Retain sharper blade edges and crisper grind lines

- Improve consistency in finish and minimize cleanup

- Create a cleaner working environment

Precise Control and Automation with the Optional Solenoid Kit

Take control even further with the Solenoid Valve Kit, which works in tandem with the GIFM. This upgrade lets you:

- Automate gas flow by turning it on/off at specific stages of the firing process (per segment)

- Ensure gas is flowing only when needed—saving resources and increasing safety

- Achieve repeatable, precision-controlled atmospheres in your heat treating cycles

Perfect for advanced users and production settings, this upgrade transforms your kiln into a highly efficient and customizable heat treating system.

Trusted by Professionals

This system has been field-proven by bladesmiths, metalworkers, and heat treatment professionals who demand the best finish and tightest process control.

Whether you’re eliminating scale on high-carbon steel or refining your results with stainless alloys, the GIFM with optional solenoid valve gives you an edge—literally and figuratively.

No manuals available.

No wiring diagram available.

No delivery info available.