Product Information

- Description

- Additional Options

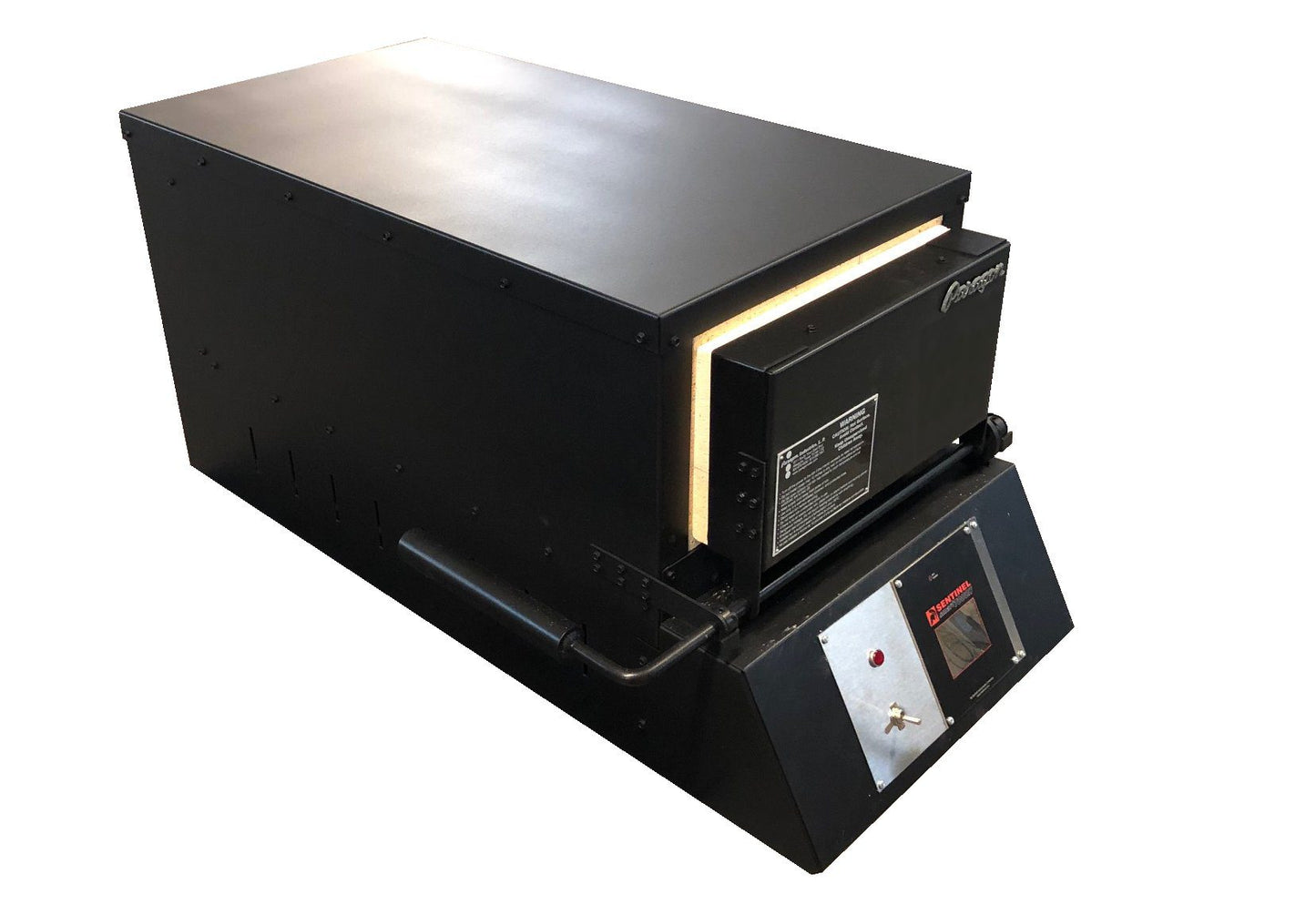

PARAGON KM24 Double Barrel: Full-Length Heat Treating with Room to Spare

The PARAGON KM24 Double Barrel is built for bladesmiths who push the limits of length, width, and complexity. With a full 24" chamber depth and a wide, tall interior profile, this kiln handles everything from long chef’s knives and swords to side-by-side batches and tall workpieces—giving you uncompromising versatility and control.

Why Have a Heat Treating Furnace in Your Shop?

Serious bladesmiths don’t just make knives—they engineer performance. The KM24 Double Barrel gives you full autonomy over time, temperature, and technique. No waiting on heat treating services. No wondering about results. With this kiln, you refine your own formulas, experiment confidently, and take your heat treating from good to exceptional.

Why Choose the PARAGON KM24 Double Barrel?

Designed for professional bladesmiths and high-output shops, the KM24 Double Barrel combines generous capacity with industrial-grade performance in a format that fits most workshops. The added chamber width and height give you more freedom to heat treat a variety of projects—without crowding or compromise.

-

Interior chamber: 13" W x 5.3" H x 24" D (1.00 cubic feet)

-

SENTINEL Touch Xpress controller: Advanced touchscreen control for fully programmable ramp, hold, and cool-down cycles.

-

Solid-state relay: Provides quiet, durable operation with superior temperature accuracy. Includes heat sink and backup safety relay.

-

3” firebrick insulation: Retains heat efficiently for uniform soak temperatures and energy savings.

-

Recessed heating elements: Safely mounted in precision-machined grooves for long-term reliability.

-

Reinforced steel construction: Built tough with a built-in stand for proper ventilation and stability.

Who is This Furnace For?

The KM24 Double Barrel is ideal for:

-

Bladesmiths producing long, wide-profile blades like chef’s knives, bushcraft knives, kukris, or short swords

-

Makers who prefer treating multiple blades or components in a single run

-

Workshops using jigs or fixtures that require more vertical or lateral space

-

Schools or labs working with varied tool geometries or extended cycle testing

Its full 24" depth combined with the spacious cross-section makes it one of the most versatile and capable furnaces in the lineup.

Drop Door Only

All KM Double Barrel kilns are equipped with a Drop Door, offering the best access to the wide chamber and a convenient staging surface when open.

Optional Upgrades

-

Gas Injection Flow Meter: Reduce scale by replacing oxygen inside the kiln with inert gas (argon, nitrogen, etc.). Available as a kit or factory-installed.

-

Add a solenoid valve: Automatically manages gas flow during your program—only flows when needed for safety and savings.

-

Knifemaking Kit: Hold and align blades for consistent and efficient hardening during every cycle.

Built with Pride in Mesquite, Texas

Every PARAGON KM24 Double Barrel is handcrafted in Mesquite, Texas, with precision, durability, and the needs of the modern bladesmith in mind. It’s the tool that gives you space to grow—literally and creatively.

No specifications available.

Get a Gas Injection Flow Meter (GIFM) and Solenoid Kit

Achieving a clean, scale-free blade finish during heat treatment isn’t just about aesthetics—it’s about quality, consistency, and minimizing post-processing time. The Gas Injection Flow Meter (GIFM) is a trusted tool among professional bladesmiths and heat treaters for precisely that reason.

Minimize Scale, Maximize Results

During high-temperature heat treating, oxygen in the kiln chamber reacts with the steel surface, producing unwanted oxidation scale. Traditionally, this has been mitigated using stainless steel foil wrap—a solution that works, but comes with added cost, time, and waste.

With the GIFM installed, you can introduce an inert gas like argon or nitrogen directly into the firing chamber. This displaces oxygen and significantly reduces oxidation, helping you:

Eliminate or reduce the need for stainless foil

Retain sharper blade edges and crisper grind lines

Improve consistency in finish and minimize cleanup

Create a cleaner working environment

Take control even further with the Solenoid Valve Kit, which works in tandem with the GIFM. This upgrade lets you:

Automate gas flow by turning it on/off at specific stages of the firing process (per segment)

Ensure gas is flowing only when needed—saving resources and increasing safety

Achieve repeatable, precision-controlled atmospheres in your heat treating cycles

Perfect for advanced users and production settings, this upgrade transforms your kiln into a highly efficient and customizable heat treating system.

This system has been field-proven by bladesmiths, metalworkers, and heat treatment professionals who demand the best finish and tightest process control.

Whether you’re eliminating scale on high-carbon steel or refining your results with stainless alloys, the GIFM with optional solenoid valve gives you an edge—literally and figuratively.

No manuals available.

No wiring diagram available.

No delivery info available.